"From Malaysia to the World"

– Continuing to Promote the UNION Brand Globally

Managing Director’s Messages

Managing Director’s Greetings

Written by Mr. Usesugi Takashi (Managing Director)

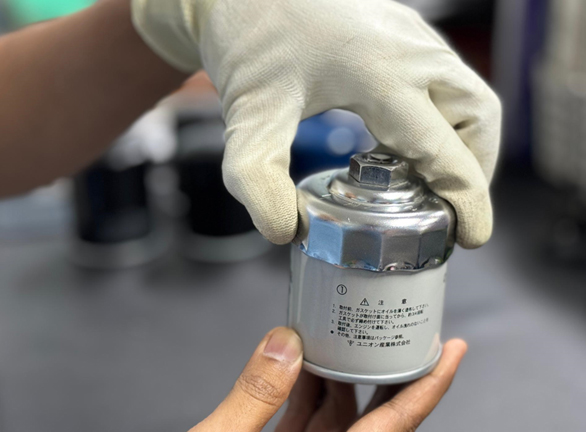

Our House Brand

Our House Brand

Our Company

Vision & Mission

Our Vision

Our Mission

KAIZEN Principle at Union Sangyo

At Union Sangyo, KAIZEN, the Japanese philosophy of “continuous improvement,” is central to our operations. We focus on making small, incremental changes to enhance our manufacturing processes, improve quality, and increase efficiency. By continuously refining our production methods and fostering a culture of open communication, we ensure our products meet the highest standards while adapting to market demands. KAIZEN drives our commitment to excellence, sustainability, and customer satisfaction, ensuring we “do it right the first time and every time.

Quality Policy

- [/] Global Market Share Position

- [/] World -class Quality Products

- [/] Bench-marked Productivity

- [/] Competitive Unit Cost

Milestone

1963

Established Union Sangyo Co., Ltd. in Toyota City, Aichi Prefecture

1968

Began operations at the Toyota Factory in Toyota City, Aichi Prefecture

1977

Began operations at the Tsushima Factory in Tsushima City, Aichi Prefecture

1988

Established Union Sangyo Malaysia in Selangor, Malaysia

1990

Began operations at Union Sangyo Malaysia in Selangor, Malaysia

1996

Established MUTSU PRINTER SDN. BHD. in Malaysia as a subsidiary to internalize the production of packaging boxes

1997

Began business relations with a major German automotive parts manufacturer

1999

Union Sangyo Malaysia obtained ISO 9001 certification

2006

- Established ZENDO RUBBER SDN. BHD. in Malaysia as a subsidiary to internalize the production of gaskets

- Organized the sales network into a system with headquarters, 3 branches, and 3 sales offices

2010

Began business relations with a major Japanese oil company

2012

Maromi Sangyo Co., Ltd. became a group company

2014

Established GIONFILTER SDN. BHD. in Malaysia as a subsidiary

2017

Union Sangyo Malaysia obtained ISO 9001:2015

2018

Launched Union Japan brand to expand the product line and enhance global market presence

2020

Responded to the global COVID-19 pandemic by implementing safety measures and maintaining operational continuity to support automotive industry needs

2022

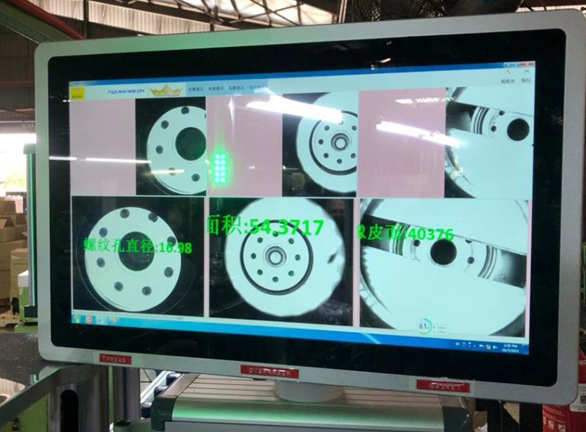

Introduced a new digital quality control system across production lines, enhancing precision and efficiency in product inspections

2023

Started business with well-known local car maker

2024

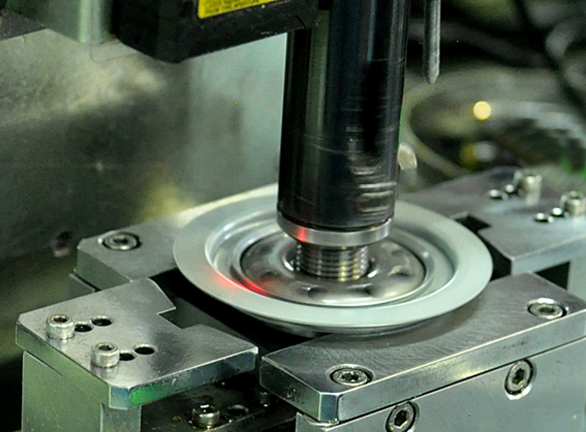

Completed a major upgrade of the Malaysian production facilities, integrating advanced quality control systems to uphold top-tier product standards

PRESENT

Union Sangyo continues to expand.

INITIAL PLANNING

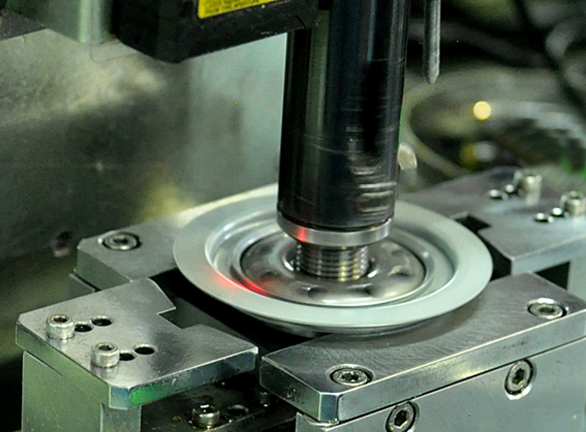

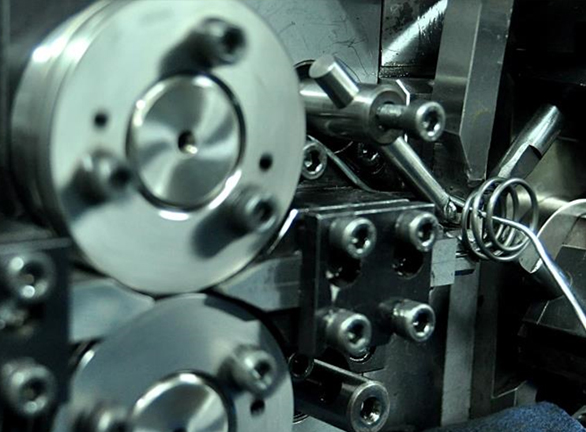

Production Environment

INITIAL PLANNING

Production Facilities

INITIAL PLANNING

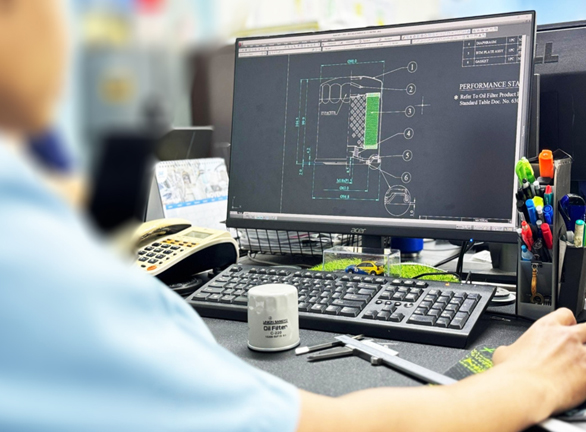

Product Development

INITIAL PLANNING

New Automation

INITIAL PLANNING

Testing Laboratory